What is Additive Manufacturing?

Additive Manufacturing, more commonly known as 3D printing. (RP), Direct Digital Manufacturing (DDM) and Additive Fabrication (AF)

Wet-immersion and dry vacuums for control of fugitive dust and housekeeping and cleaning around the 3D printing equipment.

Additive Manufacturing Hazards include potential risks that can arise from exposure to the materials used, particularly metal powders, which can be hazardous.

The best way to deal with waste dust from 3D printing is to look at the materials being used and what their properties are. At a minimum you should have HEPA filtration. Ideally, a vacuum or dust collector that is designed to be intrinsically safe and compliant with electrical and safety codes for the facility.

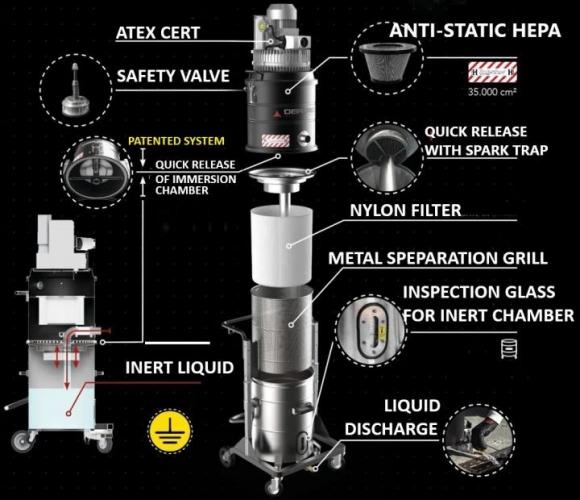

The BL AM (Additive Manufacturing) is an industrial vacuum cleaner specifically crafted to XP dust. This vacuum cleaner features a powerful single-phase brushless motor, delivering exceptional performance and maximum safety, even in potentially explosive environments. To collect dangerous particles, this product incorporates an advanced explosion-protected system: the vacuumed conductive metal powder is directly immersed in a bath of inert liquid within the container. The motor is safeguarded by a large-surface H13 class anti-static conical filter. Additional filtration inside the container ensures the highest levels of safety, even when dealing with potentially explosive dust. Inside the INERTIZATION container, there is a metal grid filter to capture any sparks and a nylon filter that separates the sucked metal dust from the inert liquid, allowing for recovery and reuse.

The BL AM eliminates the health hazards of additive manufacturing dust with its state of the art INERTIZATION chamber and muliple filter statges, with a HEPA at the exhaust allowing the unit to double as a HEPA air cleaner returning clean breathable air back into the workspace.

Click HERE to see a brochure with full specifications

Designed and built in Italy, the BL Additive Manufacturing vacuum is a state of the art 3D printing vacuum ideal for labs and areas where cleanliness and clean breathable air is crucial for workers' safety.

| Motor | Primary Filter | Machine |

|---|---|---|

| Motors | Type Brushless Motor | Filter Type Cartridge | Dimensions 21.6 x 24.4 in |

| Voltage | Frequency 120 | 60 V|Hz | Class EN 60335-2-69 H13 | Height 55 in |

| Maximum Vacuum 92 inH2O | Media Antistatic Polyester | Weight 110 lb |

| Maximum Air Flow 129 CFM | Surface Area 5,500 in² | Bin Capacity 12 gal |

| Noise Level-(EN ISO 3744) 72 dB(A) | Hydrogen Vent Valve Included | |

| Frequency 50/60 Hz | ||

| Power 1.5 HP | ||

| IP | Insulation Class 65 | F | ||

| Inlet 2 Ø in |

Additive Manufacturing, more commonly known as 3D printing. (RP), Direct Digital Manufacturing (DDM) and Additive Fabrication (AF)

The 3D printers used in additive manufacturing usually require cleaning after the process is completed as the dusts can be explosive. Some explosive dusts also interact badly with other explosive dusts. Control of fugitive dust emissions and housekeeping outside of (and around) the 3D printing equipment must also be considered.

Whether the powders or materials used are metal or nonmetal, it is imperative that anyone considering using additive manufacturing perform a risk analysis on the process to determine the hazards involved and how those hazards will be managed.

Controlled Air Design offers a complete line of vacuum cleaners for additive manufacturing and 3D Printing. We offer both immersion “wet mix” systems as well as dry recovery systems.

The materials used in additive manufacturing can range from starch to photopolymer resins (polymer changes properties when exposed to light) to thermoplastics to metals, such as aluminum, titanium, stainless steel, Inconel alloys, and others.

OSHA created the Nationally Recognized Testing Lab (NRTL) program to ensure that certain types of equipment be tested and certified for their safe use in the workplace. A Nationally Recognized Testing Laboratory (NRTL) is a private-sector organization that OSHA has recognized as meeting the legal requirements in 29 CFR 1910.7 to perform testing and certification of products using consensus-based test standards. An organization must have the necessary capability both as a product safety testing laboratory and as a product certification body to receive OSHA recognition as an NRTL. To find out more about the OSHA NRTL program, please follow this link to the OSHA website: https://www.osha.gov/dts/otpca/nrtl/nrtllist.html

Our Statmax Conductive vac hoses specification sheets contain resistance readings that show the concentration of conductive resins used: https://www.controlledairdesign.com/images/uploads/files/StatMax_YL_1.pdf

For applications where a grounding wire is called for, we have the food grade StatMax with copper grounding wire: https://www.controlledairdesign.com/products/hoses-tools/statmax-grounded

Highly portable and ergonomic XP dust collector for collection of ST1 XP Dust for batching and pouring. Built in Italy, cleverly designed, small footprint, and very easy to maintain. Parts and filters are always on hand. Portable units and arms are usually in stock for immediate shipment.

Click HERE to see a brochure with full specifications